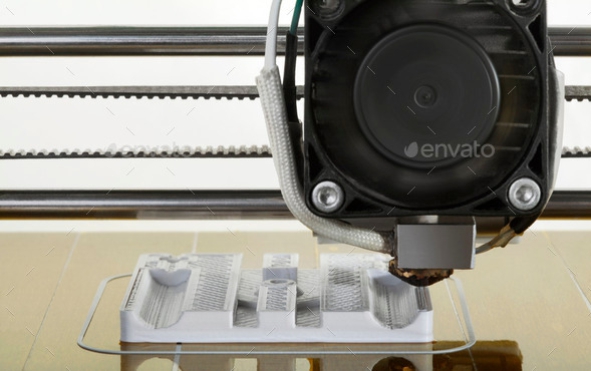

Prototyping

More often than not, new designs present unexpected problems. We use the 3D design tool to create the design. The design is analysed using the tools at our disposal and, when we are satisfied, we then commit to a prototype. There is nothing more satisfying than seeing a physical part that you can touch and share with your colleagues.

The transformation from an IDEA to REALITY.

Prototyping allows us the chance to evaluate the deign and answer any queries. It’s also an opportunity to explore options for design alternatives, test theories and confirm performance prior to mass production.

Crucially, prototyping saves companies a great deal of money by allowing changes to be made early on in the process. Design changes after mass production will be far more costly than correcting issues in the early stages.

Prototyping allows IDEAS to evolve into REALITY.

We use the latest technologies and with the help of our network of suppliers we can manage the process of creating the prototype.

We offer 3D printing, Laser cut and folded Sheet-metal and Vacuum Formed plastic to CNC machined parts to create the solution.

Let S3 Design provide you with the solution.